With the booming development of new energy vehicle industry, DC charging pile, as the key facility for rapid charging of electric vehicles, is gradually occupying an important position in the market, and BeiHai Power (China), as a member of the new energy field, is also making important contributions to the popularisation and promotion of new energy. In this article, we will elaborate on the DC charging piles in terms of application technology, working principle, charging power, classification structure, usage scenarios and characteristics.

Use of technology

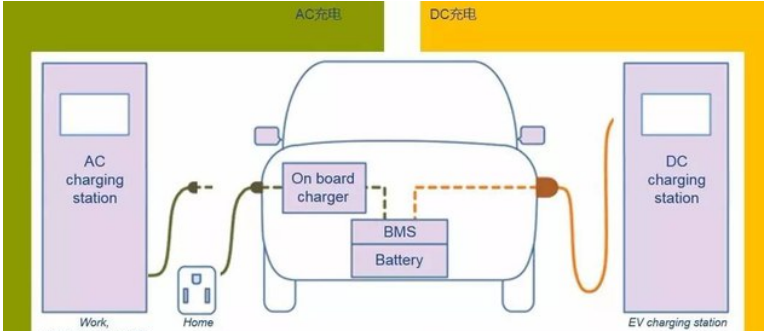

DC charging pile (referred to as DC charging pile) adopts advanced power electronic technology, and its core lies in the internal inverter. The core of the inverter is the internal inverter, which can efficiently convert AC energy from the power grid into DC energy and directly supply it to the battery of the electric vehicle for charging. This conversion process is done inside the charging post, avoiding the loss of power conversion by the EV on-board inverter, which significantly improves the charging efficiency. In addition, the DC charging post is equipped with an intelligent control system that automatically adjusts the charging current and voltage according to the real-time status of the battery, ensuring a safe and efficient charging process.

Working Principle

The working principle of DC charging pile mainly involves three aspects: power conversion, current control and communication management:

Power conversion: DC charging pile firstly needs to convert AC power to DC power, which is realised by the internal rectifier. The rectifier usually adopts a bridge rectifier circuit, which is composed of four diodes, and can convert the negative and positive halves of the AC power into DC power respectively.

Current control: DC chargers need to control the charging current to ensure the safety and efficiency of the charging process. The current control is realised by the charging controller inside the charging pile, which can dynamically adjust the size of the charging current according to the demand of the electric vehicle and the capacity of the charging pile.

Communication management: DC charging piles usually also have the function of communicating with the electric vehicle to realise the management and monitoring of the charging process. The communication management is realised through the communication module inside the charging pile, which can carry out two-way communication with the electric vehicle, including sending charging commands from the charging pile to the electric vehicle and receiving status information of the electric vehicle.

Charging power

DC charging piles are known for their high power charging capability. There are a variety of DC chargers on the market, including 40kW, 60kW, 120kW, 160kW and even 240kW. These high power chargers are able to quickly replenish electric vehicles in a short period of time, greatly reducing charging time. For example, a DC charging post with a power of 100kW can, under ideal conditions, charge an electric vehicle’s battery to full capacity in about half an hour to an hour. The supercharging technology even increases the charging power to more than 200kW, further shortening the charging time and bringing great convenience to electric vehicle users.

Classification and Structure

DC charging piles can be classified from different dimensions, such as power size, number of charging guns, structural form and installation method.

Charging pile structure: DC charging piles can be classified into integrated DC charging pile and split DC charging pile.

Charging facility standards: can be divided into Chinese standard: GB/T; European standard: IEC (The International Electrotechnical Commission); U.S. standard: SAE (Society of Automotive Engineers of United States); Japanese Standard: CHAdeMO (Japan).

Charging gun classification: according to the number of charger guns of the charging pile can be divided into single gun, double guns, three guns, and can also be customised according to the actual demand.

Internal structure composition of charging post:The electrical part of DC charging post consists of primary circuit and secondary circuit. The input of the main circuit is three-phase AC power, which is converted into DC power acceptable to the battery by the charging module (rectifier module) after inputting the circuit breaker and AC smart meter, and then connected to the fuse and charger gun to charge the electric vehicle. The secondary circuit consists of charging pile controller, card reader, display screen, DC meter, etc. It provides ‘start-stop’ control and ‘emergency stop’ operation, as well as human-machine interaction equipments such as signal light and display screen.

Usage Scenario

DC charging piles are widely used in various places that need quick replenishment of electricity due to their fast charging characteristics. In the field of public transport, such as city buses, taxis and other high-frequency, high-traffic operating vehicles, DC charging pile provides a reliable fast charging solution. In highway service areas, large shopping malls, public car parks and other public places, DC charging piles also provide convenient charging services for passing electric vehicle users. In addition, DC charging piles are often installed at specialised sites such as industrial parks and logistics parks to meet the charging needs of specialised vehicles in the park. With the popularity of new energy vehicles, residential neighbourhoods have also gradually begun to install DC charging piles to provide charging convenience for residents’ electric vehicles.

Features

High efficiency and speed: The power conversion of DC charging pile is completed within the pile, avoiding the loss of on-board inverter and making charging more efficient. At the same time, the high power charging capacity enables electric vehicles to be quickly recharged in a short period of time.

Widely applicable: DC charging piles are suitable for a variety of use scenarios, including public transport, specialised stations, public places and residential communities, etc., to meet the charging needs of different users.

Intelligent and safe: DC charging piles equipped with an intelligent control system can monitor the battery status in real time and automatically adjust the charging parameters to ensure the safety and stability of the charging process.

Promote the development of new energy vehicles: the wide application of DC charging pile provides strong support for the popularity of new energy vehicles and promotes the rapid development of new energy vehicle industry.

Post time: Jul-17-2024